08/26/2019 | Press Releases

Kuraray at K 2019 in Düsseldorf: Sustainable materials for a greener future

Speciality chemicals manufacturer Kuraray is exhibiting the recyclable barrier resin EVAL™, SEPTON™ BIO-series TPE raw materials, PLANTIC™, CLARINO™, MonoSol, Mowital®, SEPTON™, HYBRAR™, KURARITY™, KURARAY POVAL™, MOWIFLEX™ and GENESTAR™ in Hall 7a, Booth D06 at K 2019.

Hattersheim/Düsseldorf, August 2019. Sustainability and environmental protection are key topics for the plastics and rubber industries. Modern materials have to be produced sustainably and be biodegradable or recyclable. At the same time, they have to meet the high demands made by industry, for example, on mechanical strength. At K 2019 in Düsseldorf, Germany, on October 16-23, 2019, Kuraray, one of the world's leading speciality chemicals producers, is presenting its extensive range of brands - EVAL™, SEPTON™ BIO-series, PLANTIC™, CLARINO™, MonoSol, Mowital®, SEPTON™, HYBRAR™, KURARITY™, KURARAY POVAL™, MOWIFLEX™ and GENESTAR™ - in Hall 7a, Booth D06. Materials like the new EVOH copolymer EVAL™, which is readily recyclable, and the bio-based TPE SEPTON™ BIO-series are unique materials that combine performance with sustainability.

“As one of the leading speciality chemicals producers, we have a special responsibility to pay attention to the environment,” says Dr. Matthias Gutweiler, Managing Director of Kuraray Europe. “Therefore, we are stepping up our focus on sustainability in the development of new materials and the optimisation of our own processes. At K 2019 we are showcasing our wide range of innovative materials such as the sustainable bio-based barrier material PLANTIC™ and our SEPTON™ BIO-series of bio-based TPE raw materials.” This speciality chemicals producer is presenting its wide range of environment-friendly, high-performance materials at K 2019 in Düsseldorf Germany, the world's leading specialist trade show for the plastics and rubber industries, from October 16-23, 2019. At booth D06 in Hall 7a, Kuraray's experts will be providing information on the following products:

- The SEPTON™ BIO-series – A range of highly elastic bio-based TPE raw materials with very good flow ability and adhesion, good grip performance and better damping properties than conventional hydrogenated styrene block copolymers.

- EVAL™ – The new EVOH copolymer grades are even easier to recycle thanks to their low ethylene content that allows lower thicknesses. As packaging materials, they protect food optimally to prolong shelf life.

- PLANTIC™ - This biopolymer is 80 percent starch. Its outstanding oxygen barrier facilitates high-performance packaging that is completely biodegradable.

- Monosol – This PVA film is biodegradable and dissolves completely in water. It can be used as a substitute for single-use plastic packaging in many applications to reduce plastic waste.

- CLARINO™ Suede – This sustainable, animal-friendly alternative to leather is produced using a particularly environment-friendly process without any animal-based products.

- MOWIFLEX™ – These water-soluble polyvinyl alcohols biodegrade within a short time in fresh water - a fact confirmed by TÜV Austria. They are suitable for environment-friendly applications from 3D printing to the lost-core process.

In addition, at K 2019 Kuraray’s experts will be providing information on the company's wide range of other high-performance materials such as HYBRAR™, with its outstanding vibration damping and shock absorbent properties and the acrylic block copolymer KURARITY™, which has excellent purity, making it especially suitable for use in light guide applications. Moreover, visitors can find out about the exceptional strength of GENESTAR™ polyamide resin, which is particularly suitable for automotive connectors because of its heat resistance. “In Düsseldorf, we are also presenting the granulated grades of our Mowital™ poylvinylbutyrate (PVB) materials, which are especially suitable for 3D printing, and Mowital® Thin Film, which makes composites highly stable,” says Jörg Bruss, Director of Global Business, Technical PVB at Kuraray.

Below you will find more detailed information on the sustainable polymers SEPTON™ BIO-series, EVAL™, PLANTIC™, MonoSol, CLARINO™ Suede and MOWIFLEX™, which Kuraray is showcasing at K 2019 in Düsseldorf, together with photos:

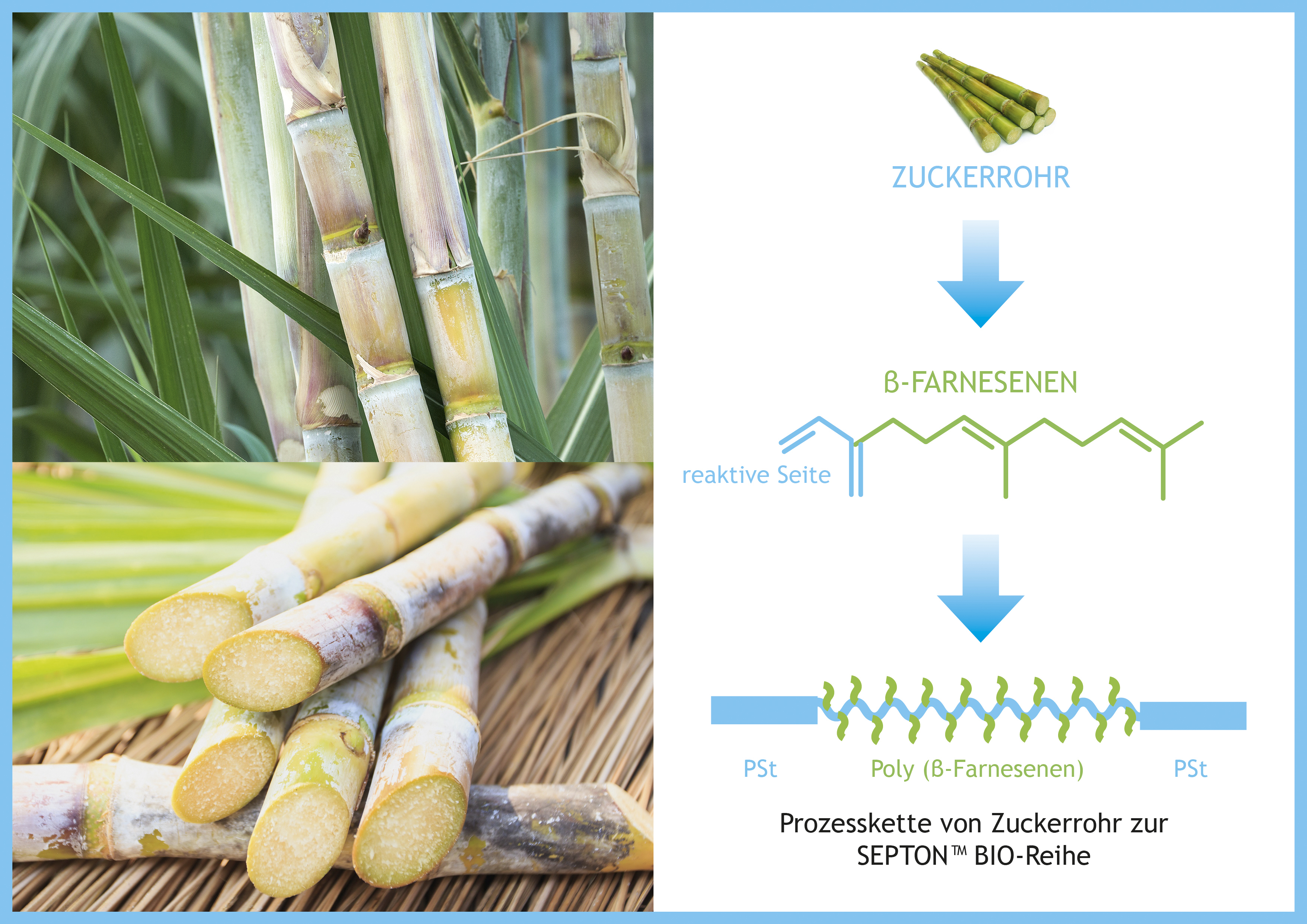

Bio TPE based on sugar cane: a better performance with less crude oil

“SEPTON™ BIO-series, based on natural, renewable resources, is a new addition to our range of TPE materials. As one of the leading suppliers of TPE, we are responding to rising demand from industry for more sustainable materials,” says Jan-Sebastian Weber, Senior Sales Manager at Kuraray. “This hydrogenated styrene farnesene block copolymer (HSFC) is particularly easy to process thanks to its very good flow ability and adhesion. It does not require any additional plasticisers and has a broader damping range than conventional hydrogenated styrene block copolymers (HSBC).” SEPTON™ BIO-series materials are based on β-farnesene, a renewable monomer derived from sugar cane. In fermentation processes, proprietary yeast strains convert the sugar into β-farnesene. The TPE raw materials are ideal for applications in adhesives, sealants, gels, films, and soft compounds and are used with their unique grip performance in the manufacture of handles, for example for sports equipment.

Simple recycling of multi-layer plastic packaging

EVAL™ EVOH copolymer resin creates an impermeable layer for use in co-extrusion and co-injection processes. Its high-performance oxygen barrier properties make it an optimum packaging material, for example for dry foods such as coffee and dehydrated milk: it keeps out gases such as oxygen and keeps in the flavour of the food. It maintains its barrier properties even after heat treatment and can be used for retort packaging as a substitute for materials like glass, aluminium or tin. In addition, there are advantages in the recycling process: adding 10 percent PP-EVOH recycling material from industrial sources to recycled PCR-PP or PCR-HDPE from domestic refuse collections did not affect food-safe cleaning, further processing or the physical properties of the recyclables compared to PCR-PP or PCR-HDPE alone. This addition corresponds to 5 times the proportion currently detectable in the recycling of PP materials. “We are presenting a completely new grade of our EVAL™ EVOH copolymer at K 2019,” says Hiroyuki Shimo, President of Kuraray Eval Europe. “Its particularly low ethylene content facilitates the development of more easily recyclable multi-layer structures. It therefore makes an important contribution to more efficient use of resources.”

Fully sustainable: biodegradable starch-based barrier material

“Kuraray's PLANTIC™ is a unique alternative barrier packaging material that is geared entirely to sustainability,” says Stefan Corbus, Market Development Engineer at Kuraray. “Since it is more than 80 percent starch and is produced from renewable raw materials that have not been genetically modified, the optimised carbon footprint and biodegradability of this biopolymer minimise its environmental impact.” It acts as an excellent barrier to atmospheric oxygen, making it ideal for packaging sensitive foods such as coffee and snacks as well as dry animal feedstuffs. As a 50 µm thick monolayer film, PLANTIC™ can be laminated to various materials. For example, in combination with paper it can be used to produce fully biodegradable packaging. Since PLANTIC™ is soluble in water, laminates with non-biodegradable materials are easy to separate for simple and safe recycling.

Edible films to reduce pollution

“Our MonoSol brand of water-soluble PVA films has revolutionised the detergents industry,” says Yash Parulekar, Senior Manager, Global Product Stewardship at Kuraray. “Leading consumer goods manufacturers use these films, for example, for laundry and dishwasher pods. We are exhibiting our new edible films at K 2019. Uses include packaging for protein and meal replacement shakes, food colorants, spices, cooking oil, pasta, rice, oats and flour.” The films produced using MonoSol technology dissolve completely in water, are biodegradable and do not cause impurities in recycling chains or pollute the environment with microplastics. Their outstanding barrier properties and superior sustainability profile make them an ideal substitute for many single-use plastic packaging materials. In addition, the films can be used in personal hygiene and cosmetic products such as shampoos, conditioners and soap.

Animal and environment-friendly: completely solvent-free man-made leather

CLARINO™ Suede is a sustainable alternative to leather. It is produced without any animal-based products. This suede-look microfibre nonwoven is water-borne and production is animal and environment-friendly. In addition, CLARINO™ Suede is highly versatile: this heat-resistant product can be embossed and printed. “Our new range of sustainably produced CLARINO™ Suede man-made leather has been available since the start of 2019,” says Sophie Oehler, Marketing Assistant at Kuraray. “Available in 60 shades, CLARINO™ Suede maximises flexibility when designing luxury fashion accessories such as bags - and also reduces environmental impact.”

PVA for lost-core and 3D printing processes: biodegradable and water-soluble

“Our MOWIFLEX™ polyvinyl alcohols (PVA) are ideal for thermoplastic processes such as film extrusion and injection moulding,” says Heiko Mack, Head of Poval Business at Kuraray. “These materials are soluble in water and biodegradable. That makes them an environment-friendly solution for the production of hollow shapes in the lost-core process. They can also be used for professional 3D printing.” MOWIFLEX™ 3D 2000 support filament allows the production of precise support structures for 3D printing of filigree and overhanging structures. After printing, it can simply be washed off with water, without leaving any contact marks on the object. That ensures optimum printing results. MOWIFLEX™ is fully biodegradable in fresh water within a short time, meets the requirements of ISO 14851 and can be disposed of conveniently in an environmentally compatible manner through normal wastewater systems. That is confirmed by the “Vinçotte OK biodegradable” certificate awarded by TÜV Austria.

About Kuraray

Established in 1991, Kuraray Europe GmbH is based in Hattersheim, near Frankfurt am Main, Germany. In 2018 the company generated annual sales of EUR 690 million. It has approximately 700 employees in Germany at its sites in Hattersheim, Frankfurt and Troisdorf. Kuraray is a global speciality chemicals company and one of the largest suppliers of industrial polymers and synthetic microfibres for many sectors of industry. Examples are KURARAY POVAL™, Mowital®, Trosifol® and CLEARFIL™. Kuraray Europe also has around 200 employees at six other European sites. They are also working on the development and application of innovative high-performance materials for a wide range of sectors, including the automotive, paper, glass and packaging industries, as well as for architects and dentists.

Kuraray Europe is a wholly owned subsidiary of the publicly listed company Kuraray Co., Ltd., which is based in Tokyo, Japan, and has more than 10,000 employees worldwide and sales of EUR 4.8 billion.

Press contacts at K 2019:

Robin Conrad

Marketing & CRM

Kuraray Europe GmbH

Philipp-Reis-Straße 4

65795 Hattersheim am Main

Phone: +49 69 305 85933

E-Mail: robin.conrad(at)kuraray.com

Internet: www.elastomer.kuraray.com

Contacts for trade press inquiries:

Dr. Bettina Plaumann

Head of KEG Communications & Marketing

Kuraray Europe GmbH

Philipp-Reis-Straße 4

65795 Hattersheim am Main

Tel.: +49 69 305 85797

E-Mail: Bettina.Plaumann(at)kuraray.com

Internet: www.kuraray.eu

www.elastomer.kuraray.com

Christopher Kampfmann

Wortwahl – Agentur für Unternehmens- und Onlinekommunikation

Bahnhofstraße 123

63263 Neu-Isenburg

Tel.: +49 6102 36678-22

E-Mail: kampfmann(at)wortwahl.de

Internet: www.wortwahl.de

>> Download this press release as an adobe acrobat document here

[Photos 1 and 2] High grip-performance based on sugar: the TPE raw materials in the SEPTON™ BIO-series are produced sustainably from β-farnesene obtained from renewable sugar cane. Thanks to its good flow ability, adhesion properties and wide damping range, this material is superior to conventional thermoplastic elastomers in many applications.

[Photo 3] EVAL™ offers advantages in recycling: adding 10 percent PP-EVOH recycling material from industrial sources to recycled PCR-PP or PCR-HDPE from domestic refuse collections does not affect food-safe cleaning, further processing or physical properties compared to PCR-PP or PCR-HDPE alone.

[Photo 4] Completely sustainable packaging: PLANTIC™ biopolymer is biodegradable and contains more than 80 percent renewable starch. Its excellent barrier performance keeps out oxygen and makes sure the flavour and aroma of coffee, snacks and sweets stay inside the packaging.

[Photos 5 and 6] Water-soluble and edible films reduce packaging waste: applications for the MonoSol brand of PVA films include water-soluble detergent pods (photo left). At K 2019 Kuraray is showcasing its new edible films produced from this water-soluble, biodegradable PVA. These films can be used to package spices, oil and protein shakes (photo right).

[Photo 7] Versatile, environment-friendly and animal-friendly: CLARINO™ Suede from Kuraray is a sustainable alternative to leather. This man-made leather is produced from start to finish using an environmentally friendly process without any solvents. It is available in 60 shades to maximise flexibility when designing luxury fashion accessories such as bags.

[Photo 8] Sustainability from 3D printing to lost core: MOWIFLEX™ PVA materials from Kuraray are water-soluble and biodegrade in cold water within a short time. That is confirmed by the “Vinçotte OK biodegradable” certificate from TÜV Austria. The materials can be used in many thermoplastic processing methods. MOWIFLEX™ 3D 2000 is used as a support filament in 3D printing, allowing the production of complex, filigree and overhanging structures.

News Archive 2024

News Archive 2024