03/23/2021 | Press Releases

High-speed network and mixed reality headset for film production: Kuraray is testing 5G applications in Troisdorf

Speciality chemicals producer Kuraray is involved in a research project funded by the German government to test innovative 5G technologies in industry - including mixed reality and real-time sensors for tomorrow's manufacturing processes.

Hattersheim/Troisdorf, March 23, 2021. The new 5G standard paves the way for technologies that bring massive changes for industry, both now and in the future. In a unique research project at Troisdorf Industrial Park in Germany, partners from science and industry are exploring how innovative 5G technology can make industrial processes faster, more efficient and more sustainable. The Federal Ministry of Transport and Digital Infrastructure (BMVI) is providing funding of EUR 3.57 million for this project. The project partners include Kuraray, one of the world's leading speciality chemicals producers, which has its European headquarters in Hattersheim, Germany, and sites in Frankfurt and Troisdorf. Kuraray is working intensively to make Germany and Europe technology hubs that are fit for the 5G era. For example, it markets innovative materials that significantly improve the performance of fibre optic cables and high-performance electronic components (further information: www.kuraray.eu/materials-for-5g). In the pilot project in Troisdorf, Kuraray is testing a virtual toolbox comprising a mixed reality (MR) headset for remote monitoring and maintenance of industrial plant and new sensors for real-time control of manufacturing processes.

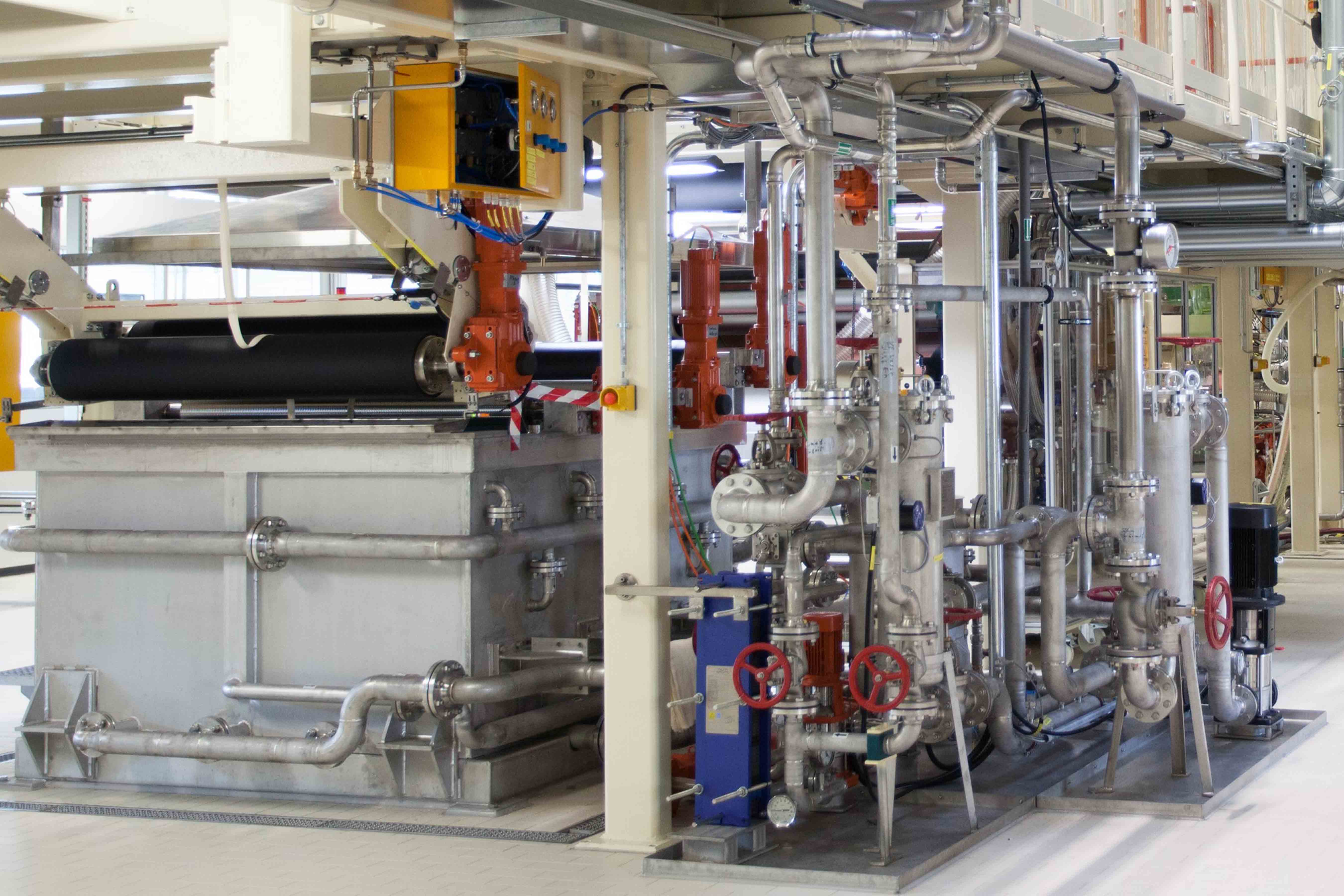

“Our project at Troisdorf Industrial Park is exceptional because the latest research findings are being translated directly into practical applications,” says Dr. Holger Stenzel, Kuraray site manager in Troisdorf. “With our project partners from science, such as the Fraunhofer Institute for Applied Information Technology (FIT), we are examining the opportunities that the new 5G standard offers industry.” At its site in Troisdorf, Kuraray produces high-quality PVB films, which are used as interlayers in demanding safety glass for architecture and the automotive sector. One application being tested by Kuraray in Troisdorf as part of the project is a 5G toolbox, for example for remote maintenance of production facilities or service assignments for customers.

5G toolbox and mixed reality headsets for maintenance and repair of industrial facilities from home

New technologies such as MR headsets give process engineers and technicians at speciality chemicals producer Kuraray an accurate overview of installations and access to additional information such as real-time data, operating instructions and engineering plans. “The 5G toolbox enables our engineers to obtain a detailed overview of the situation, regardless where they are, and to give on-site personnel accurate instructions, for example, to eliminate faults,” says Dr. Holger Stenzel. “These new technologies mean that in future we can link our employees’ specialist skills even better and create completely new and more flexible ways of working. Even our technicians could then work from home.”

Real-time sensors to control PVB film production in milliseconds

In addition, Kuraray is testing how new sensors in a 5G network could improve the quality and efficiency of production. “Production of our PVB films involves the interaction of a number of complex process steps. To achieve the best quality for our customers, our processes are fine-tuned to fractions of seconds,” says Simon Fuchs, Global Demand Manager at Kuraray, who is leading the project in Troisdorf. “Until now, very complex cabling was necessary to monitor the various parameters affecting production.” In the pilot project, Kuraray and researchers from the Fraunhofer Institute are examining how 5G sensors can provide an even more precise overview of process flows. Real-time data could optimize workflows even further - which would improve quality and reduce waste, emissions, energy consumption during production. Together with ZWi Technologies, another company based at Troisdorf Industrial Park, Kuraray is also testing a smart control system for the forklifters used at the site.

EUR 3.57 million from the German government for research into industrial 5G networks

The pilot project in Troisdorf is one of ten projects where the Federal Ministry of Transport and Digital Infrastructure (BMVI) is supporting research into industrial applications for 5G technologies. BMVI is providing total funding of EUR 3.57 million for the three-year project in Troisdorf, which was launched in January 2021. The next steps are realizing the individual applications and setting up the 5G campus network. Alongside Kuraray, ZWi Technologies and Troiline GmbH, a subsidiary of the municipal utility Stadtwerke Troisdorf, which is installing the entire independent 5G campus network, the project includes the Troisdorf economic development agency Trowista. The other partners are three highly regarded scientific organizations: the Fraunhofer Institute for Applied Information Technology (FIT), the Institute for Technology and Innovation Management at RWTH Aachen University, and ILAG institute for work, performance and society.

5G pilot project at Troisdorf Industrial Park

The 5G pilot project in Troisdorf is providing key information on how 5G can make industrial processes better, more efficient, and more environment-friendly.

- Aim of the project: The seven partners in the project consortium are testing innovative 5G applications for industry at Troisdorf Industrial Park. One area of focus is completely new concepts that were not viable with the 4G standard such as secure remote maintenance of installations with an MR headset, and a smart control system for forklifters.

- Project schedule: The project started in January 2021 and is scheduled to run for 3 years. The first step comprises developing application cases. In parallel, a 5G campus network that is completely independent of the telecommunications network is being installed at Troisdorf Industrial Park. The project partners will then integrate the individual industrial applications into this network.

- Cross-sector approach: The project brings together partners from a variety of sectors. Alongside Kuraray and ZWi Technologies, both of which have operations at Troisdorf Industrial Park, the consortium comprises Trowista (the economic development agency of the municipality of Troisdorf) and Troiline GmbH. On the scientific side, the project is receiving support from the Fraunhofer Institute for Applied Information Technology (FIT), the Institute for Technology and Innovation Management at RWTH Aachen University and ILAG institute for work, performance and society.

- Key facts: Given the importance of Germany and Europe as a base for industry, the Federal Ministry for Transport and Digital Infrastructure (BMVI) is providing total funding of EUR 3.57 million for the pilot project in Troisdorf.

About Kuraray

Established in 1991, Kuraray Europe GmbH is based in Hattersheim, near Frankfurt am Main, Germany. In 2020 the company generated annual sales of EUR 593 million. It has more than 800 employees in Germany at its sites in Hattersheim, Frankfurt and Troisdorf. Kuraray is a global speciality chemicals company and one of the largest suppliers of industrial polymers and synthetic microfibres for many sectors of industry. Examples are KURARAY POVAL™, Mowital®, Trosifol® and CLEARFIL™. Kuraray Europe also has around 215 employees at six other European sites. They are also working on the development and application of innovative high-performance materials for a wide range of sectors, including the automotive, paper, glass and packaging industries, as well as for architects and dentists.

Kuraray Europe is a wholly owned subsidiary of the publicly listed Kuraray Co., Ltd., which is based in Tokyo, Japan, and has more than 11,200 employees worldwide and sales of EUR 4.4 billion.

Dr. Bettina Plaumann

Head of KEG Communications & Marketing

Kuraray Europe GmbH

Philipp-Reis-Straße 4

65795 Hattersheim am Main, Germany

Phone: +49 69 305 85797

Email: Bettina.Plaumann(at)kuraray.com

Internet: www.kuraray.eu

Christopher Kampfmann

Wortwahl – Agentur für Unternehmens- und Onlinekommunikation

Bahnhofstraße 123

63263 Neu-Isenburg, Germany

Phone: +49 6102 36678-22

Email: kampfmann(at)wortwahl.de

Internet: www.kuraray.eu

>> Download this press release as an adobe acrobat document here

Captions/source of photos: Kuraray / BMVI

5G for tomorrow’s production processes: In a unique research project at Troisdorf Industrial Park, partners from science and industry are exploring how innovative 5G technology can improve industrial processes and make them more sustainable. Speciality chemicals company Kuraray is part of the project consortium. For example, it is testing the industrial benefits of real-time sensors and mixed-reality headsets at its PVB film production facilities in Troisdorf (photo above left). The German government is providing funding of EUR 3.57 million for the project (logo source: BMVI).

Science meets industry: “Our project to test new industrial 5G technologies at Troisdorf Industrial Park is combining the latest research findings directly with practical applications,” says Dr. Holger Stenzel, Kuraray site manager in Troisdorf. “Together with project partners from the world of science such as the Fraunhofer Institute, we are testing the industrial opportunities offered by the new 5G standard - from real-time sensors to a virtual toolbox.”

Enabling engineers and technicians to work from home: Simon Fuchs, Global Demand Manager at Kuraray, who is leading the project in Troisdorf, demonstrates how personnel could perform maintenance work on complex facilities from home in future with the aid of an MR headset: “In the pilot project in Troisdorf, we are testing new technologies such as a digital toolbox that could permanently alter industrial workflows. As one of ten projects selected by the Federal Ministry of Transport and Digital Infrastructure, we are at the forefront of the development of new 5G technologies and playing a part in making industry in Germany and Europe fit for the 5G age.”

Real-time sensors for high-tech film production: At its site in Troisdorf, Kuraray produces high-quality PVB films, which are used as interlayers in safety glazing for demanding architectural and automotive applications. Together with researchers from the Fraunhofer Institute (FIT), Kuraray is testing how new 5G sensors can improve quality and reduce waste, emissions and energy consumption.

News Archive 2024

News Archive 2024