Contact

Contact

Do you have any questions,

need technical support or

would like to place an order?

Order form

Kuraray Europe GmbH Sustainability Blog Kuraray proudly presents: Trosifol® R3

Contact

Contact

Do you have any questions,

need technical support or

would like to place an order?

It was one of the product launches of the year: at the end of 2024, Kuraray presented its newly developed Trosifol® R3 at the glasstec trade show in Düsseldorf, Germany. This innovative addition to the Trosifol product family drew amazement from the trade world because it sets new standards for sustainability. It reduces CO2 emissions in production by up to 90 percent compared with the manufacture of conventional PVB glass interlayers. As well as facilitating demanding glazing projects, Trosifol® R3 significantly reduces their carbon footprint.

Laminated safety glass that meets the highest technical and aesthetic standards is typically used in architecture and vehicles. Here too, producers and engineers are expected to cut emissions and play their part in minimizing climate change. Now, Trosifol® R3 offers them a way of achieving exactly that. Trosifol® R3 interlayers are (or soon will be) ISO-certified, which includes all environmental product declarations. At the same time, they have all the properties that have positioned Kuraray for many years as a market leader in PVB interlayers.

"We are proud to present this innovative product class to our customers, so we can advance the transition to more sustainable materials in the sector,” says Alberto Alarcon, Global Marketing Communication Manager at Kuraray’s Advanced Interlayer Solutions (AIS) division.

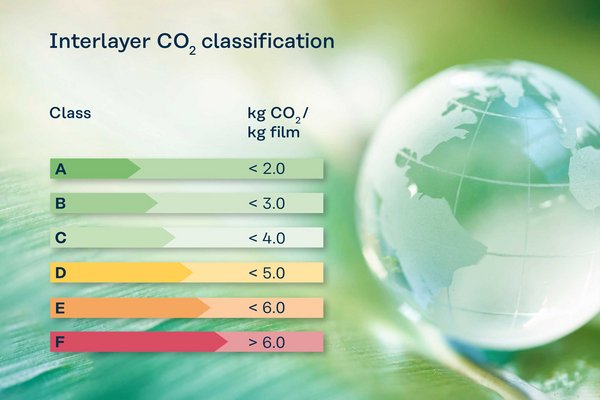

The new premium interlayer Trosifol® R3 is embedded in a broad and sustainable value chain. The product line contains optimized materials and is manufactured very efficiently using clean energy to minimize damaging environmental impacts. Ecologically, the best in class product is Trosifol® R3 Clear Class A. This PVB interlayer is manufactured in widths of up to 2.40 metres and has the lowest available carbon footprint: just 0.19 kilograms CO2 per kilogram film produced. Trosifol® R3 Clear Class B also helps reduce direct and indirect greenhouse gas emissions. This jumbo format product is available in a maximum width of 3.21 metres and reduces emissions by around 1.75 kilograms to 2.7 kilograms CO2 per kilogram film.

Like Trosifol® R3, different variants of all other glass interlayers produced by Kuraray are available on the market. “Based on the life cycle assessment of our products, we have developed a transparent CO2 classification analogously to the established system of energy efficiency classes used for domestic appliances,” explains Christoph Troska, Head of New Market Development at Kuraray’s AIS division. “This allows simple comparison of the relative greenhouse gas potential of our materials. The two Trosifol® R3 product variants are assigned to the highest classes, A and B, and are therefore optimally positioned to help our customers achieve their sustainability goals.”

R3 stands for Reuse – Reduce – Recycle. In our AIS division, R3 is used to describe initiatives and solutions that have a positive sustainability impact along the entire value chain. That can be the reuse of packaging, the use of recyclable materials or a product like Trosifol® R3, which reduces the carbon footprint of glass structures. To help our customers with the selection of products, we offer Carbon Reduce AI, a new tool based on artificial intelligence for rapid and simple determination of the carbon footprint of glass structures. This tool is a good example of how innovation, sustainability and digitalization go hand in hand at Kuraray.

For more information on Trosifol® R3 go to:

www.trosifol.com Sustainable Glazing: Trosifol® R3 – Clear. Strong. Sustainable