Contact

Contact

Do you have any questions,

need technical support or

would like to place an order?

Order form

Contact

Contact

Do you have any questions,

need technical support or

would like to place an order?

Autonomous driving, smart factories, internet of things (IoT), new communication technologies: The 5G standard is paving the way for digitalization-driven megatrends. New high-performance materials are needed to enable the high data rates required for self-driving cars and machine-to-machine (M2M) communication in Industry 4.0.

Use these innovative materials from Kuraray in your 5G applications and benefit from the unique properties of the SEPTON™ Q-Series, Vecstar™ and GENESTAR™.

As one of the world's leading specialty chemicals producers, Kuraray markets innovative materials to help industry develop advanced 5G technologies. Here are three examples: SEPTON™ Q-Series elastomers provide lasting protection for sensitive optical fibers. Vecstar™ liquid crystal polymer film maximizes the flexibility of printed circuit boards for high-speed transmission components, and the heat-resistant polyamide GENESTAR™ is excellent for the production of high-speed data connectors with the SMT reflow soldering process.

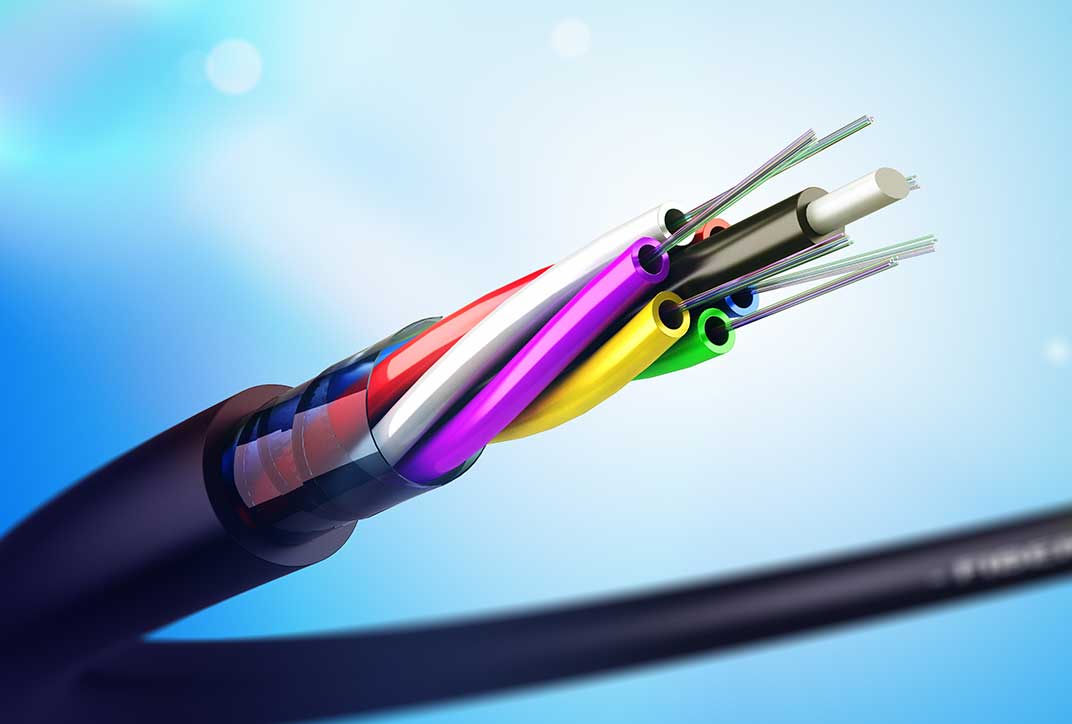

Fiber optic cables are extremely important for the rollout of the 5G network. As the underground link between radio masts and base stations, they facilitate extremely high data rates The SEPTON™ Q-Series high-performance elastomers from Kuraray have very high scratch and abrasion resistance, so casings made of these products ensure exceptionally good protection of sensitive fiber optic cables. Blends with SEPTON™ Q-Series as the base polymer also maintain their elasticity at very hot and cold temperatures, under water, in steam and in tropical climates. Moreover, they are far lighter than conventional materials such as TPU and TPC. In addition, they have very good insulating properties, ensuring secure and stable data transmission in the 5G network and in high-speed transmission components in modern automotive and communication devices.

Find out more about the benefits of SEPTON™ Q-Series for your applications

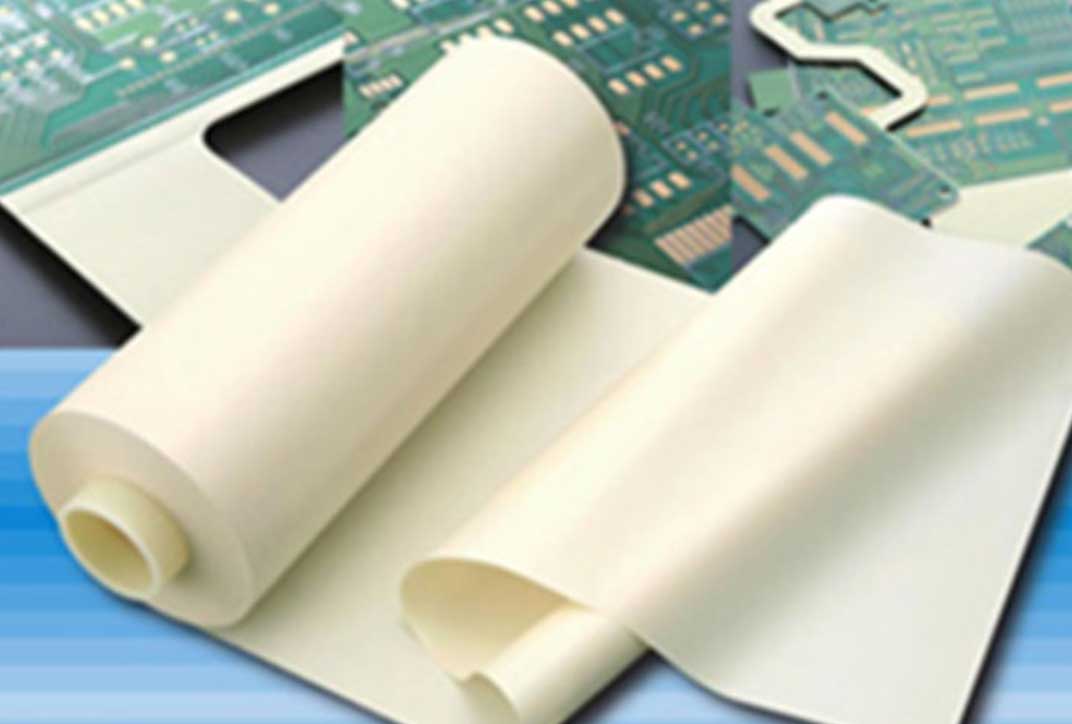

Vecstar™, the world’s first LCP film, offers outstanding properties for the manufacture of high-performance electronic components. The dielectric properties of this homogeneous material from Kuraray minimize transmission losses in high-frequency communication. Thanks to their low water absorbency, outstanding heat resistance and dimensional stability, these LCP films are ideal for high-speed switches and high-frequency electronic devices. Vecstar™ is used as a substrate for flexible printed circuit boards. This copper-clad laminate (FCCL) has unique flexibility, which permits the production of curved and multi-layer circuits — for maximum freedom in the design of innovative technologies.

GENESTAR™ PA9T is a chemical and heat resistant polyamide produced by Kuraray. Thanks to its low water absorption and excellent mechanical properties, GENESTAR™ PA9T is already used in many demanding applications in the automotive, electrical and electronics industries – for example SMT connectors. Compared with other PPAs, GENESTAR™ PA9T has the highest tracking resistance, even when exposed to humidity and temperature fluctuations. The excellent dielectric properties of this product make it ideal for high-speed data connectors like 5G applications in vehicles. Additional benefits: GENESTAR™ PA9T is easier to process than PPS and has a higher weld line strength than LCP. Moreover, it is easier to colorise compared to LCP and PPS materials. It also has a outstanding dimensional stability making GENESTARTM PA9T suitable for high precision parts.

Find out how you can use GENESTAR™ PA9T in your applications